1

/

of

5

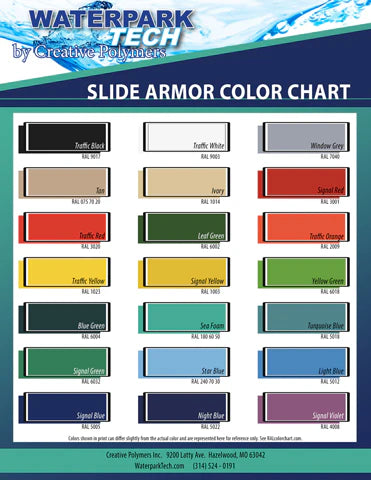

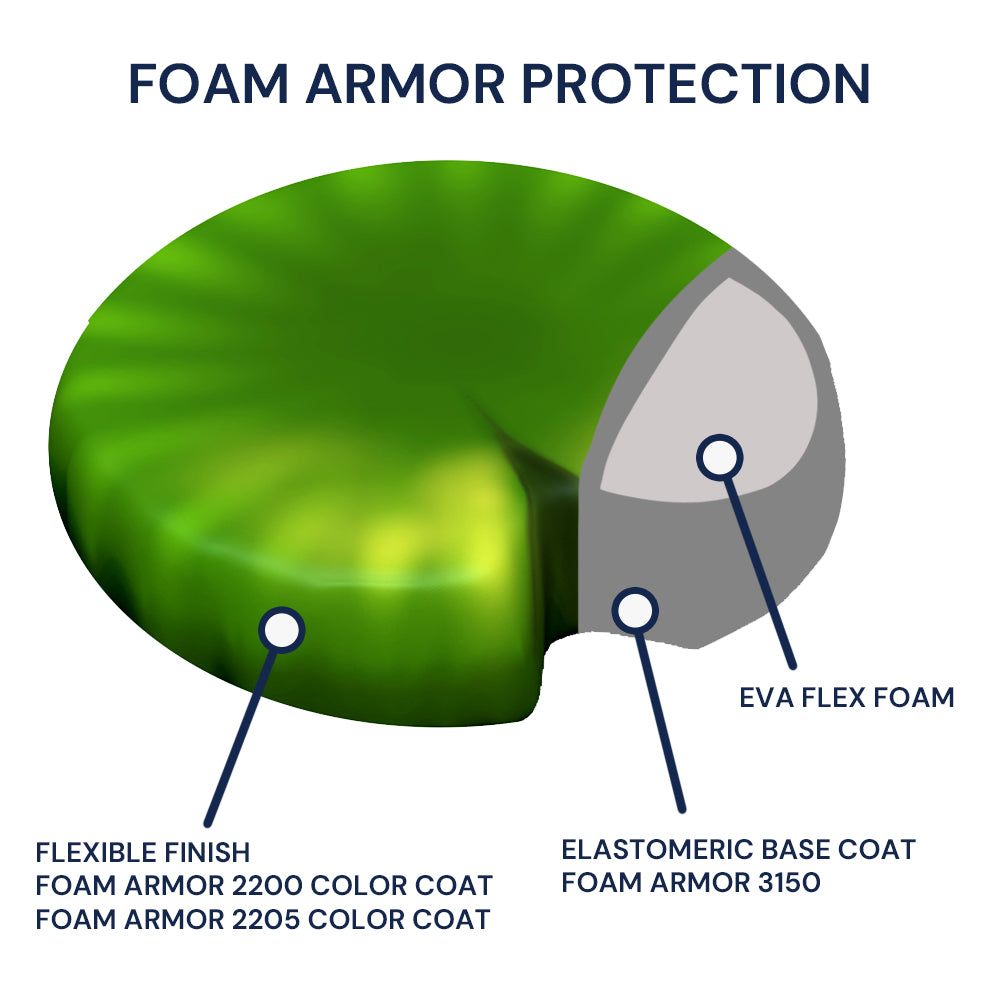

Foam Armor 2200 Color Coat

Foam Armor 2200 Color Coat

Regular price

$410.00 USD

($273.33 per gallon)

Regular price

Sale price

$410.00 USD

($273.33 per gallon)

Unit price

/

per

For contractor and large project pricing call or email Creative Polymers directly

Couldn't load pickup availability

Flexible Alphatic "Soft Tech" Finish. The TT 2200 is a specialty alphatic polyurethane designed as the flexible /elastomeric color coat and provides outstanding color and gloss resistance and durability

Share